Job-Shop Scheduling with Cooperative Transportation Resources (JSTP-C)

The Job-Shop scheduling Problem (JSP) is one of the most known problems in the domain of production task scheduling. The Job-Shop scheduling Problem with Transportation resources (JSPT) is a generalization of the classical JSP and consists of jointly scheduling production operations and transport operations which are performed by automated vehicles also called mobile robots.

In this work, the JSPT is examined from a more general perspective, where each transport operation can require the simultaneous use of several specialized robots due to the unique characteristics and handling requirements of each job, encompassing factors like size, weight, and fragility. The originality of this work lies in considering the JSPT environment with the assumption that a transport operation may require the cooperation of several robots in carrying a job from a machine to another which requires proper synchronization between robots over time. We call this new variant the Job-Shop scheduling Problem with Cooperative Transportation resources (JSTP-C). To the best of our knowledge, this problem has never been studied before. Note that synchronization issues appear in other problems, including the Vehicle Routing Problem where the synchronization can involve, for instance, vehicles, drivers, or medical staff.

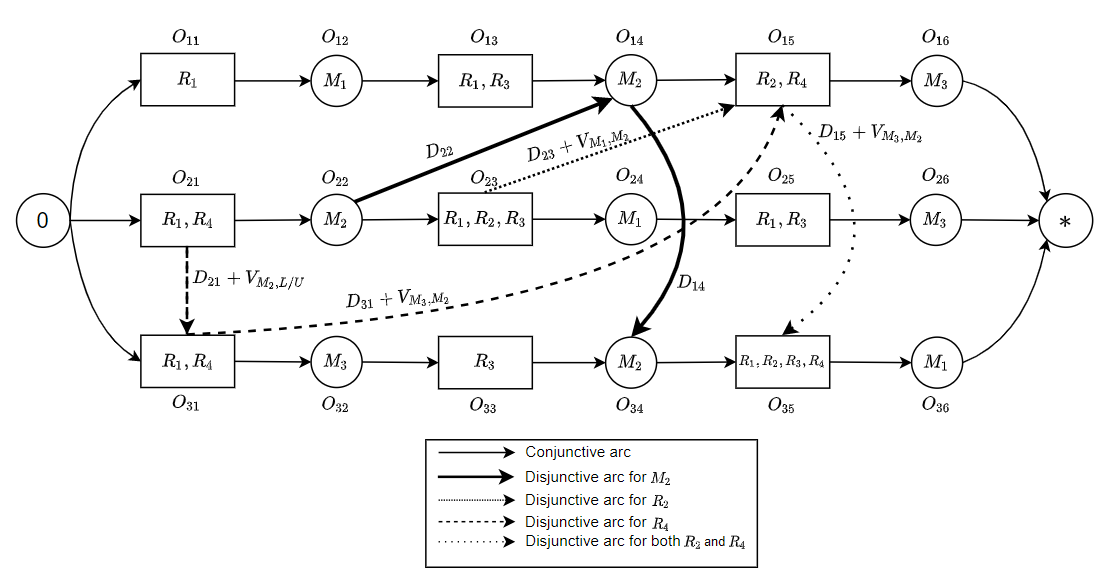

Figure: (Partial) oriented acyclic disjunctive graph representing a feasible solution.

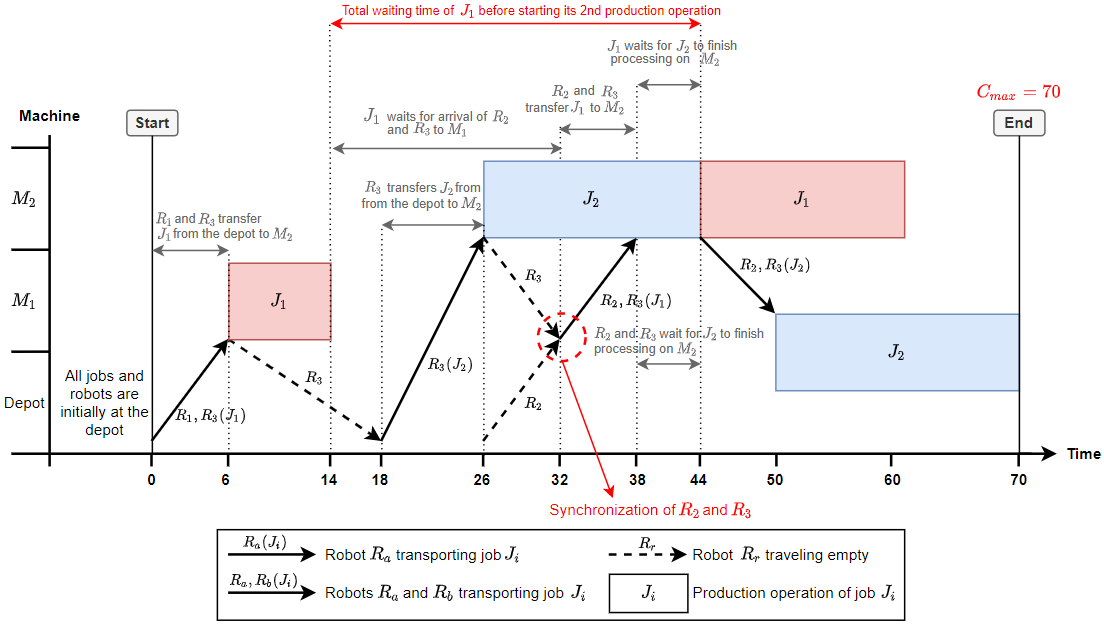

Figure: Gantt chart representation of a solution.

Job-Shop Scheduling with Flexible Poly-Robot Configurations (JSPT-FC)

The Job-Shop Scheduling Problem with Flexible Poly-Robot Configurations (JSPT-FC) is a continuation of the JSPT-C (Job-Shop Scheduling Problem with Transport and Cooperation). While the JSPT-C models transportation operations performed by cooperative robots with a fixed number of participants, the JSPT-FC extends this framework by introducing flexible poly-robot configurations, where the number of cooperating robots for each transportation task becomes a decision variable. This flexibility allows the system to adapt robot team sizes dynamically, introducing new trade-offs between speedup, synchronization delays, and parallelism. Increasing the number of cooperating robots can accelerate transport through shared load handling but also raises synchronization and coordination challenges.

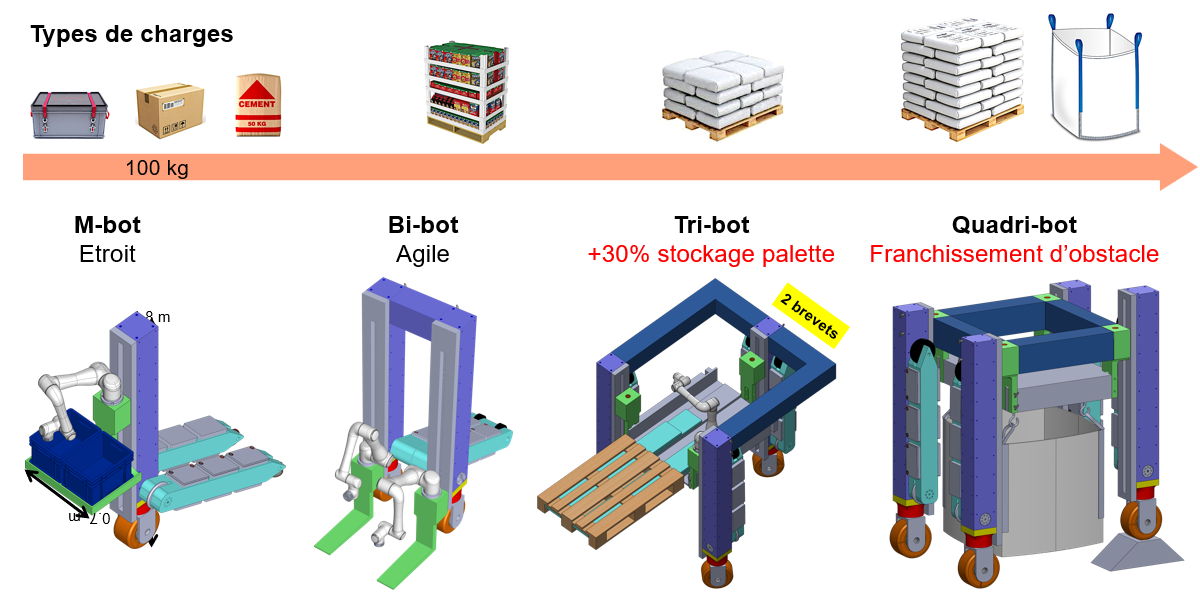

Figure: Different poly-robot configurations developed by Mecabotix company .