|

|

Multi-Periods

Job-Shop Scheduling Problem

|

|

|

|

|

|

|

|

|

C. Duhamel |

J. Fontanel |

P. Lacomme |

P. Pelissier |

N. Tchernev |

I.

Description

This paper addresses the multi-period multi

products job-shop scheduling problem. At each period the shop has a limited

capacity and each product has a given demand. This problem is generalizations

of the job-shop scheduling problem where several job-shops must be solve

tackling a maximal finish time. The number of periods considered is denoted ![]() and is designates the bound of the schedule

horizon. For each period the objective consists in defining if a job-shop

solution exists such that all job finished dates are upper bounded by the

period capacity and when no solution exists to determine which job must be

deleted in the period and forwarded to a previous one. A storage costs and a

production costs are addressed to evaluate the global costs of a solution. The

multi-period multi products job-shop scheduling problem is a step forwards the

MRP II in classical computer aided manufacturing management system. The Job-Shop Scheduling Problem (JSSP) is a

well-known optimization problem often used in practical scheduling applications

in the manufacturing sector. The JSSP can be formulated as follows: a set of

and is designates the bound of the schedule

horizon. For each period the objective consists in defining if a job-shop

solution exists such that all job finished dates are upper bounded by the

period capacity and when no solution exists to determine which job must be

deleted in the period and forwarded to a previous one. A storage costs and a

production costs are addressed to evaluate the global costs of a solution. The

multi-period multi products job-shop scheduling problem is a step forwards the

MRP II in classical computer aided manufacturing management system. The Job-Shop Scheduling Problem (JSSP) is a

well-known optimization problem often used in practical scheduling applications

in the manufacturing sector. The JSSP can be formulated as follows: a set of ![]() jobs

jobs ![]() has to be processed on a set of

has to be processed on a set of ![]() machines

machines ![]() . Each job is fully defined by an

ordered (linear) sequence of operations that are associated with a particular

machine. Therefore, the dimension of the problem is often denoted as

. Each job is fully defined by an

ordered (linear) sequence of operations that are associated with a particular

machine. Therefore, the dimension of the problem is often denoted as ![]() . In addition, the JSSP must satisfy

other constraints such as: (i) no more than one operation of any job can be

executed simultaneously; (ii) no

machine can process more than one operation at the same time; (iii) the job operations must be

executed in a predefined sequence and once an operation is started, no

preemption is permitted.

. In addition, the JSSP must satisfy

other constraints such as: (i) no more than one operation of any job can be

executed simultaneously; (ii) no

machine can process more than one operation at the same time; (iii) the job operations must be

executed in a predefined sequence and once an operation is started, no

preemption is permitted.

Each operation ![]() is associated with a particular job

is associated with a particular job ![]() and machine

and machine ![]() and has a duration

and has a duration ![]() . The objective is to schedule each

operation on the machines, taking the precedence constraints into account such

that the total makespan (

. The objective is to schedule each

operation on the machines, taking the precedence constraints into account such

that the total makespan (![]() ) is minimized. The Multi Period Job-Shop Scheduling Problem

consists in

) is minimized. The Multi Period Job-Shop Scheduling Problem

consists in ![]() Job-Shop Scheduling Problems which must be

solved consecutively trying to access to a makespan less than the capacity of

the period. The capacity represents a number of units of time available for

processing and a job-shop solution is stated as feasible if the makespan (the

completion time of the last operation) is less than the capacity. For each

period we consider a production cost in euros per jobs and for each job,

storage cost in euros per unit of time per job. This problem is close to the

problem of integration of lot sizing and scheduling problems formulated by [1]

[2]. The problem consists in defining a job-shop solution for each period and

determining which job must be backwarded.

Job-Shop Scheduling Problems which must be

solved consecutively trying to access to a makespan less than the capacity of

the period. The capacity represents a number of units of time available for

processing and a job-shop solution is stated as feasible if the makespan (the

completion time of the last operation) is less than the capacity. For each

period we consider a production cost in euros per jobs and for each job,

storage cost in euros per unit of time per job. This problem is close to the

problem of integration of lot sizing and scheduling problems formulated by [1]

[2]. The problem consists in defining a job-shop solution for each period and

determining which job must be backwarded.

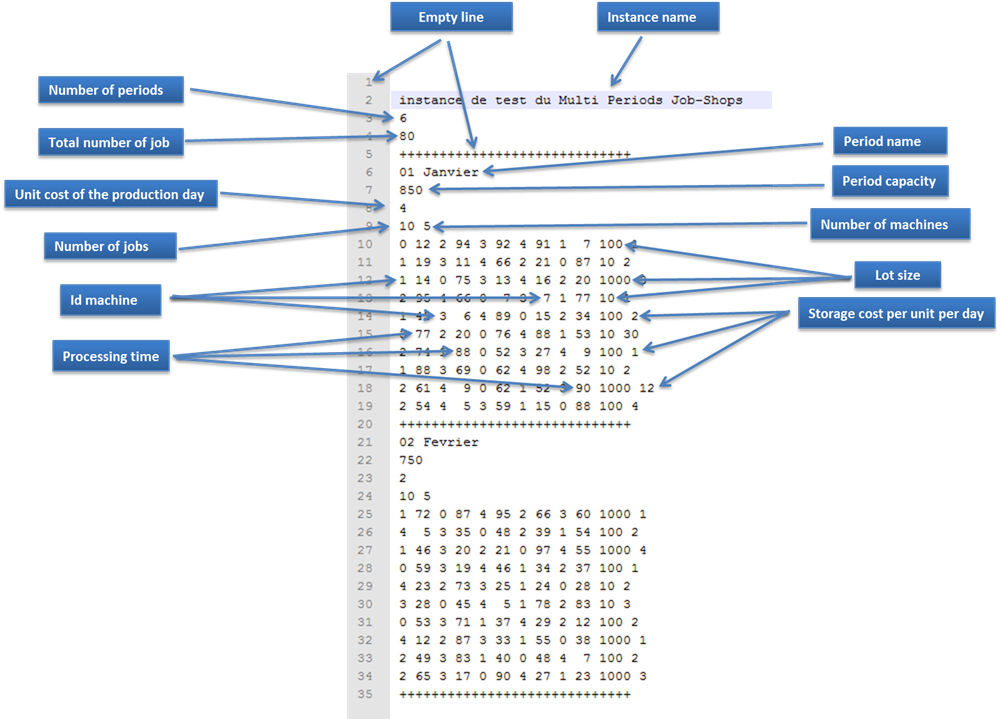

II.

File description:

III.

Instances:

|

Instances |

Description |

Number of periods |

Number of jobs |

Download Instances |

Download Solutions |

|

LA01-JSSP |

Based on Lawrence instance LA01 |

6 |

68 |

||

|

LA02-JSSP |

Based on Lawrence instance LA02 |

6 |

66 |

||

|

LA03-JSSP |

Based on Lawrence instance LA03 |

6 |

55 |

||

|

LA04-JSSP |

Based on Lawrence instance LA04 |

6 |

67 |

||

|

LA05-JSSP |

Based on Lawrence instance LA05 |

6 |

58 |

||

|

LA06-JSSP |

Based on Lawrence instance LA06 |

6 |

64 |

||

|

LA07-JSSP |

Based on Lawrence instance LA07 |

6 |

86 |

||

|

LA08-JSSP |

Based on Lawrence instance LA08 |

6 |

Come soon |

|

|

|

LA09-JSSP |

Based on Lawrence instance LA09 |

6 |

Come soon |

|

|

|

LA10-JSSP |

Based on Lawrence instance LA10 |

6 |

Come soon |

|

|

|

LA01-10-JSSP |

Instances LA01 to LA10-JSSP |

/ |

/ |

||

IV.

Reference:

[1] S. Dauzère-Pérès and J.B. Lasserre. Integration of lot sizing

and scheduling decisions in a job-shop. European

Journal of Operational Research, 75(2):413-426, 1994.

[2]

S. Dauzère-Pérès, J.B. Lasserre,

An Integrated Approach in Production Planning and Scheduling, Lecture Notes in Economics and Mathematical

Systems, Springer Verlag, Berlin, 1994.

[3] Bierwirth

C. A generalized permutation approach to jobshop

scheduling with genetic algorithms. OR Spektrum. Vol. 17, pp. 87-92, 1995

[4] Nowicky E. and C. Smutnicki. A fast taboo search algorithm for the job-shop problem. Management Science. 42 (6). 797-813. 2006.